پروژه های انجام شده آرتین آزما مهر

شرکت آرتین آزما با تمرکز بر اجرای پروژههای تخصصی و تأمین تجهیزات پیشرفته، به عنوان یکی از شرکتهای پیشرو در صنایع شیمیایی و آزمایشگاهی شناخته میشود.

این شرکت با ارائه کاتالیستهای باکیفیت و خدمات حرفهای، مسیر رشد و موفقیت را برای مشتریان خود هموار میسازد.

تأمین کاتالیست ایزومریزاسیون سولفات زیرکونیا پالایشگاه شیراز، شرکت جندی شاپور

طرح توسعه پالایشگاه شیراز به منظور افزایش کیفیت و تونع محصولات. در این پروژه واحد ایزومریزاسیون نفتا به منظور تولید بنزین با کیفیت یورو 5 توسط مجری طرح (شرکت جند ی شاپور)

محل انجام پروژه:

شیراز

کارفرما:

پالایشگاه شیراز – شرکت جندی شاپور

مدت زمان اجرا:

4 ماه ماه

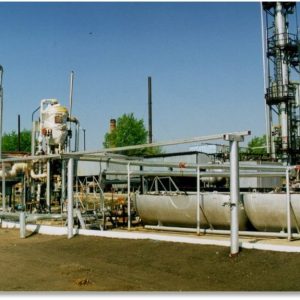

پروژه واحد DMC، پارس جنوبی فاز دو و سه

طراحی فرآیند و ارائه لایسنس به همراه تأمین کاتالیست در پروژه ساخت واحد مرکاپتانزدایی از میعانات گازی پالایشگاه فازهای ۲ و ۳ پارس جنوبی(DMC)با ظرفیت فرآورش روزانه ۸۰ هزار بشکه بهمنظور تکمیل زنجیره ایجاد ارزش افزوده پالایشگاه، کاهش آثار خوردگی ترکیبات مضر موجود بر تأسیسات و تجهیزات پالایشگاهی، کاهش آلایندههای زیستمحیطی، ارتقا و بهبود کیفیت میعانات گازی، سهولت در بازاریابی، صادرات و…

محل انجام پروژه:

عسلویه – منطقه ویژه اقتصادی پارس جنوبی

کارفرما:

شرکت نفت و گاز پارس

مدت زمان اجرا:

24ماه ماه

پروژه آزمایشگاه آب پتروشیمی دماوند

تامین کلیه تجهیزات آزمایش آب، نصب و راه اندازی و آموزش مجتمع پتروشیمی دماوند به منظور راه اندازی 70 هزار متر مکعب در ساعت آب خنک کننده، 32 متر مکعب در ساعت آب شیرین، 660 تن در ساعت بخار، 246 مگاوات برق، 156 تن در ساعت اکسیژن و 48 هزار نرمال متر مکعب در ساعت نیتروژن.این پتروشیمی نیازهای جانبی (آب، برق و بخار) مورد نیاز واحدهای فرآیندی مستقر در منطقه یژه اقتصادی انرژی پارس (عسلویه) را تأمین می کند. خوراک این مجتمع 610 میلیون متر مکعب در سال گاز طبیعی است که از فازهای توسعه میدان گازی پارس جنوبی تأمین می شود و همچنین آب کندانس برگشتی مجتمع ها به میزان 410 تن بر ساعت خوراک دیگر مجتمع است.

محل انجام پروژه:

عسلویه

کارفرما:

شرکت پتروشیمی دماوند

مدت زمان اجرا:

3ماه ماه

تامین تجهیزات آزمایشگاه و کاتالیست و مواد شیمیایی پالایشگاه الپالیتو ونزوئلا

تعمیرات واحدهای عملیاتی پالایشگاه ال پالیتو ونزوئلا با هدف افزایش ظرفیت پالایشی به 140 هزار بشکه در روز و همچنین توانمندسازی پالایشگاه برای تصفیه نفت خام سنگین ایران و تولید محصولات استاندار. خدمات شرکت آرتین آزما به عنوان پیمان کار آزمایشگاه و تامین کاتالیست: تامین کلیه دستگاه های آزمایشگاهی، تامین کاتالیست مرکاپتان زدایی تولیدی شرکت صنایع شیمیایی آرتین آزما، تامین پرکلراتیلن

محل انجام پروژه:

ونزوئلا

کارفرما:

شرکت ملی مهندسی و ساختمان نفت ایران

مدت زمان اجرا:

180 روز ماه

ساخت و تجهیز آزمایشگاه پالایشگاه هویزه خلیج فارس NGL 3200 اهواز

پروژه طراحی و ساخت سکوبندی و همچنین تامین تمامی دستگاه های آزمایشگاهی برای پروژه احداث کارخانه گاز و گاز مایع 3200 در جنوب غربی شهر اهواز و غرب رودخانه کارون به منظور جمع آوری گازهای همراه حاصل از فرآورش نفت میادین حوزه غرب کارون شامل میادین نفتی دارخوین، یادآوران، آزادگان جنوبی و آزادگان شمالی. همچنین ساخت مبلمان آزمایشگاهی، خطوط انتقال گاز دستگاه های کروماتوگرافی، ساخت GC Room، تامین تمام تجهیزات آزمایشگاهی، تامین مواد شیمیایی و رفرنس ها، نصب و راه اندازی و آموزش.

محل انجام پروژه:

استان خوزستان غرب کارون

کارفرما:

هلدینگ خلیج فارس

مدت زمان اجرا:

286 روز ماه