Introduction

Atmospheric distillation is one of the most important separation methods in the oil and petrochemical industry. This process uses the difference in boiling points of various components to separate them into different fractions. Since petroleum products are a mixture of hydrocarbons with different boiling points, distillation tests play a crucial role in evaluating the properties and quality of these materials. One of the global standards for conducting these tests is the ASTM D86 method. In this article, we will explain the process of atmospheric distillation testing, its applications, and the ARNS21 device designed for this specific test.

What is Atmospheric Distillation?

Atmospheric distillation is an industrial process where a liquid mixture is separated into its constituent components. This process is particularly useful in oil refineries for separating crude oil into various fractions. During this process, materials are separated due to differences in their boiling points, with each component being separated at a specific temperature.

Under atmospheric conditions, i.e., at normal atmospheric pressure (around 101.3 kPa), different hydrocarbon compounds with varying boiling points are separated from each other. The primary goal of atmospheric distillation is to separate lighter hydrocarbons, such as gasoline and diesel, from heavier materials like kerosene and heavy oils.

ASTM D86 Method

ASTM D86 is one of the global standard methods for conducting atmospheric distillation tests. This method, developed by the American Society for Testing and Materials (ASTM), is widely used in laboratories and the petroleum industry. ASTM D86 is particularly applicable for determining the distillation characteristics of petroleum products like gasoline, kerosene, diesel fuel, and other similar products.

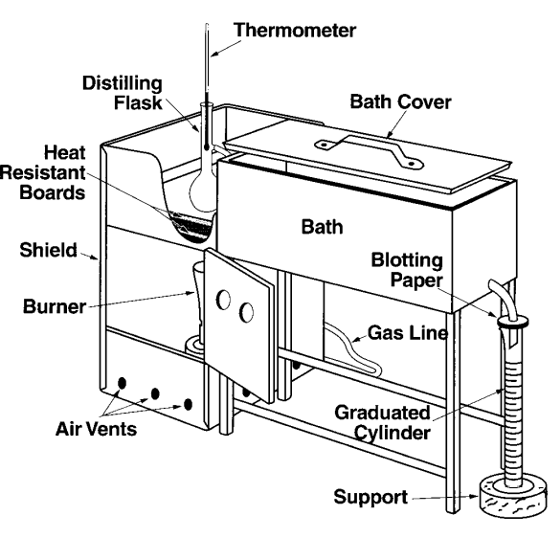

This method involves heating the sample in a distillation apparatus until its various components evaporate sequentially at their respective boiling points and are collected. This process helps determine the temperatures at which each fraction of the material distills, and the results are crucial for assessing fuel quality and determining the performance behavior of petroleum products.

General Steps of the ASTM D86 Test:

- Sampling: First, a specified sample of the petroleum liquid is prepared and transferred to the distillation apparatus.

- Heating: The sample is gradually heated until the various components begin to vaporize.

- Collection of Vapors: The vapors are condensed through a cooling tube and collected in separate containers.

4. Recording Data: The temperatures at which each fraction distills are recorded and analyzed.

Applications of Atmospheric Distillation Tests

Atmospheric distillation tests have numerous applications in various industries, particularly in the oil and gas sector. This test not only aids in separating crude oil components but also plays a vital role in improving refinery processes and assessing the quality of final products. Some key applications of the atmospheric distillation test include:

- Evaluating Fuel Quality: Distillation testing helps identify the physical properties of liquid fuels, especially for determining boiling points and assessing fuel efficiency.

- Quality Control in Refineries: This test helps refineries control the quality of final products like gasoline, diesel, and other derivatives.

- Developing New Products: In research and development processes, distillation testing helps scientists evaluate the performance of new materials and create optimized compounds for the market.

- Compliance with International Standards: Many countries have stringent standards for the sale of petroleum products, and distillation testing is a key method for ensuring compliance with these standards.

The ARNS21 Device and Its Importance in Distillation Testing

The ARNS21 is one of the advanced devices designed for performing atmospheric distillation tests. This device is specifically optimized for conducting ASTM D86 tests and is widely used in petroleum and petrochemical laboratories. Some of the key features of the ARNS21 device include:

- High Precision: The ARNS21 is equipped with highly accurate sensors capable of measuring temperature and pressure with great precision. This feature is essential for accurately recording boiling points and ensuring optimal performance.

- Automatic Control: The ARNS21 has an automatic control system that allows for monitoring and adjusting the distillation process. This feature ensures that tests are conducted with minimal human intervention and maximum accuracy.

- High Speed: One of the common issues with older distillation devices was the time-consuming process. The ARNS21, using modern technologies, significantly speeds up the testing process.

- Advanced Cooling System: The ARNS21 is equipped with a powerful cooling system that allows for faster and more accurate collection of vapors.

Using advanced devices like the ARNS21 ensures that the results of distillation tests are more precise and reliable, which is critical for assessing the quality of petroleum products and improving refinery processes.

Conclusion

Atmospheric distillation testing is one of the most important and widely used methods in the oil and petrochemical industry. This test not only helps in separating various components of crude oil but also provides valuable information about the properties and quality of final products. The ASTM D86 method, as the global standard for conducting this test, allows companies and laboratories to ensure the accuracy and reliability of their results.

The ARNS21 device, as one of the most advanced distillation testing equipment, helps improve performance and reduce human error with its advanced features. Using this device in laboratories and the oil industry contributes to improving the quality of final products and reducing costs.

Atmospheric distillation test, ASTM D86, ARNS-21, NXA, Oil refinery standard

References: