InfraLUM FT-12 Express FT-NIR analyzer

InfraLUM FT-12 FT-NIR analyzer is designed for express and precise analysis of various agricultural and food products, enabling simultaneous determination of key parameters with utmost accuracy. With fast, one-minute analysis and typically no need for sample preparation, the instrument offers both efficiency and ease of use.

The NIR analyzer is an indispensable tool in industrial agriculture for food quality control and production process monitoring.

InfraLUM FT-12 express analyzer performs fast, non-destructive analysis of a wide range of agricultural and food products. With a single device, users can measure key nutritional values and safety parameters in cereals, flour, milk and dairy products, meat and meat products, oil and oilseeds, legumes, beverages, feed, and more.

Routinely used, this universal instrument significantly reduces analysis cost compared to common wet-chemistry techniques. It usually requires no additional sample preparation or expensive reagents and consumables. The analysis is environmentally friendly, generating no waste or pollution, and allows all parameters of interest to be measured in one run.

Thanks to FT spectroscopy, InfraLUM FT-12 ensures highly precise and reproducible results, making it a reliable choice for agricultural and food product analysis.

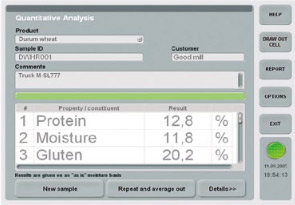

- Simultaneous determination of all parameters of interest within 1 minute

- Highest accuracy of results provided by the use of Fourier transform NIR spectrometry

- Transmission spectrum which is more informative compared to the reflectance spectrum

- Whole grain analysis with no sample preparation: no milling or grinding

- No reagents or consumables required

- Waterproof and dustproof optical compartment of the interferometer

- Open calibration models (the possibility of extending existing calibrations)

- User-friendly SpectraLUM/PRO software complied with FDA 21 CFR part 11

- IQ/OQ protocols

Lumex Instruments offers a range of models of InfraLUM FT-12 NIR analyzer to suit different needs:

- InfraLUM FT-12 universal model ideal for routine laboratory testing of any sample types;

- InfraLUM FT-12 Industrial model tailored for industrial use at processing sites and adapted to work with aggressive liquids. It features a stainless steel-protected sample compartment, an automatic locking system, antivibration platform, and programmable logic controller (PLC) as an optional upgrade. InfraLUM FT-12 Industrial model is highly recommended for liquid and paste samples analysis, and for use in industrial environments with vibrations, unstable power supply, or frequent analyzer relocation;

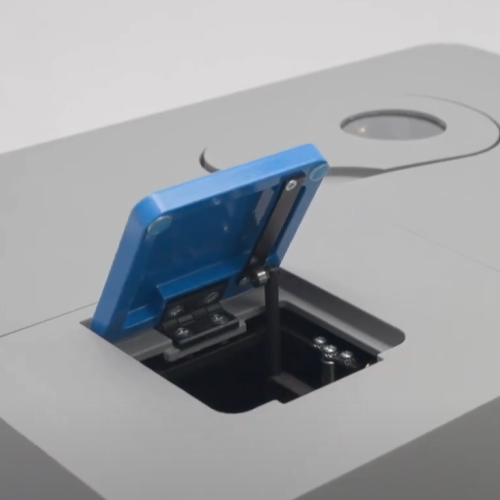

- InfraLUM FT-12 WholeGrain model equipped with the automatic cell-filling system for the rapid analysis of whole grains cereals.

InfraLUM FT-12 performs express analysis of nutritional values and safety parameters in the following food and agricultural products:

- grains, cereals, flour, and processing products (protein, moisture, fat, fiber, starch, ash, etc.);

- oilseeds, oils and processing products (oil content, protein, moisture, fiber, ash, etc.);

- feed, mixed fodders, and raw ingredients for feed production (protein, moisture, fat, fiber, amino acids, etc.);

- legumes/pulses;

- milk and dairy products (fat, protein, lactose, density, dry matter, casein, etc.);

- meat and meat products; fish and fish products (protein, moisture, fat, ash, phosphorus, calcium, etc);

- bakery products;

- sauces;

- wine;

- and many more.

The extended list of calibration models.

1. Fill the sample cell, place it into InfraLUM FT-12 / FT-12 Industrial

or fill the grain into the shaft of InfraLUM FT-12 WholeGrain,

choose the analyzed product in the menu, and start the measurement.

2. Result obtained in 1.5 minutes.

- InfraLUM FT-12 NIR analyzer (any model) with a set of cells;

- Calibration databases (in accordance with a list of parameters of interest);

- PC with Windows® OS, 2 free USB ports or PLC with a touch screen.

InfraLUM FT-12 is covered by a 1-year limited warranty.

| Measuring time |

80 sec |

|---|---|

| Sample volume |

3 – 60 ml |

| Spectral range |

13200–8700 сm-1 (760–1150 nm) |

| Resolution |

8, 16, 32, 64 cm-1 |

| Dimensions and weight |

530*450*380 mm, 32 kg |

| Power consumption |

110 W |

| Power requirements |

90-260 VAC (48-62 Hz) |

| Verification |

Once a year |

| brand |

هیچ ویدیویی برای این محصول موجود نیست.