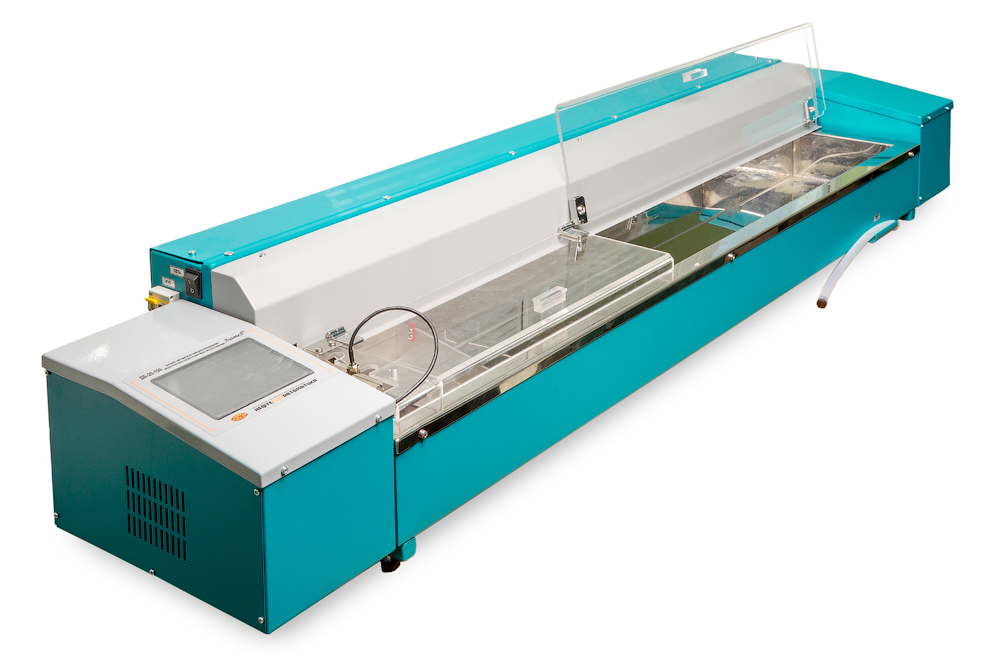

Bitumen Direct Tensile Testing Machine DB–20–100

Lintel DB-20-100 provides automatic testing of bitumen samples for ductility, elasticity, deformation energy, as well as testing of plastics and polymers for tension.

Lintel DB-20-100 provides automatic testing of bitumen samples for ductility, elasticity, deformation energy, as well as testing of plastics and polymers for tension

The device provides a specified temperature in the test zone due to the built-in thermo cryostat from -10 to +40°C

- Lintel DB-20-100 allows testing from 1 to 3 samples with a maximum breaking force of up to 30 kg per sample

- Automatic movement of the carriage at a given speed

- Integration with the Lintel Link data collection system allows for collection and transmission of laboratory test results from the device to a personal computer via wireless communication. Integration with the Lintel LIS laboratory information system provides comprehensive automation of laboratory activities.

- A built-in pump for mixing the bathhouse coolant and a modern cooling system ensure a minimum temperature gradient in different parts of the bathhouse

- Test logging provides storage of up to 100 test results and 30 sample loading graphs

- Memorization of the extensibility value and sample number in automatic mode by the drop in tension force or by the operator pressing the remote button for fixing the sample break

- Possibility of checking the temperature sensor readings of the bath with a standard thermometer

- The operator interaction system based on a color touch screen facilitates the learning and daily operation of the device

- The set of disassemblable forms for samples supplied with the device comply with GOST, ASTM, EN and provide convenient preparation of samples for testing.

- Transparent ergonomic lid

- Full self-diagnostic system with indication of causes of malfunctions on the display

- Stopping the testing process at the end of the analysis with an audible signal

- Possibility of starting the thermostat by timer – “delayed start”

Safety

Electrical safety: Grounding of non-current-carrying parts and compliance with protection class 0I according to GOST R IEC 61140-2000

Sound accompaniment: Sound signal at the end of the test, detection of a fault

Diagnostics and setup: Built-in self-diagnostics and configuration algorithms, notifying users about the causes of malfunctions

| Maximum length of elongation of test samples | 1,000 mm |

|---|---|

| The number of simultaneously tested samples | from 1 to 3 |

| Maximum load on each sample | 300 N |

| Carriage speed | from 0.1 to 100 cm / min |

| Bath volume | 17 l |

| Range of maintained bath temperature | from -10 to +40 ° C |

| Force measurement accuracy | ± 1% |

| Irregularity of the temperature of the coolant in the bath | not more than 0.5 ° C |

| Temperature measurement error | no more than ± 0.2% |

| Carriage Speed Accuracy | no more than ± 0.25 cm / min |

| Length measurement accuracy: – in the range from 0 to 300mm | no more than ± 2 mm |

| Length measurement accuracy: – in the range from 300 to 1 000mm | no more than ± 3 mm |

| Shape deviation | meet standards |

| Power consumption | no more than 650 W |

| Dimensions | 370 x 260 x 1750 mm, (depth x height x width) |

| Weight | no more than 50 kg |

| Ambient temperature | from +15 to +35 ° C |

| Relative humidity | humidity at a temperature of + 20 ° С, not more than 75% |

| Voltage | from 187 to 242 V |

| Warranty period of operation | 1 year, no more than 2 500 hours |

| Standards | ASTM D 113-99, ASTM D 6084-04, EN 13398: 2010, EN 13587: 2010, EN 13589: 2008, EN 13703: 2003 |

| brand |

هیچ ویدیویی برای این محصول موجود نیست.