Introduction

The ASTM D86 atmospheric distillation test is a crucial standardized method used to determine the physical and chemical properties of petroleum products. This test is conducted to establish the boiling range, initial boiling point, final boiling point, and distillation percentages at specific temperatures of petroleum products such as gasoline, kerosene, and diesel fuel. The data obtained from this test is instrumental in assessing fuel quality, evaluating engine performance, and selecting the most suitable product for various applications.

Purpose of the Test

The primary objective of the ASTM D86 distillation test is to determine the distillation characteristics of a petroleum product. These characteristics include:

- Initial boiling point: The temperature at which the first drop of liquid vaporizes and condenses.

- Final boiling point: The temperature at which the last drop of liquid vaporizes and condenses.

- Distillation percentages at various temperatures: The percentage of liquid vaporized and collected at specific temperatures.

- Residue: The amount of liquid remaining in the distillation flask after the test.

Applications of the Test

The ASTM D86 distillation test has a wide range of applications across various industries, including petroleum, petrochemicals, transportation, and environmental sectors. Some of the most significant applications are:

- Fuel quality control: Determining the quality of various fuels like gasoline, kerosene, and diesel and ensuring compliance with national and international standards.

- Engine performance evaluation: The distillation characteristics of petroleum products directly impact engine performance. For instance, products with lower boiling points have higher volatility and evaporate easily, which can lead to increased fuel consumption and air pollution.

- Product selection: The results of the distillation test aid in selecting the appropriate product for specific applications. For example, jet engines require products with lower boiling points, while heavy-duty diesel engines necessitate products with higher boiling points.

- Monitoring quality changes: By conducting the distillation test at regular intervals, changes in the quality of petroleum products over time can be monitored.

Test Procedure

The ASTM D86 atmospheric distillation test is performed as follows:

- Apparatus preparation: The distillation apparatus, including the distillation flask, condenser, thermometer, and receiver, is cleaned and dried.

- Sample preparation: A specific volume of the petroleum product sample is poured into the distillation flask.

- Distillation: The distillation flask is heated, and the resulting vapors are condensed in the condenser and collected in the receiver.

- Volume measurement: The volume of the liquid collected at various temperatures is measured.

- Calculations: The distillation percentages, initial boiling point, final boiling point, and residue are calculated based on the measured volumes.

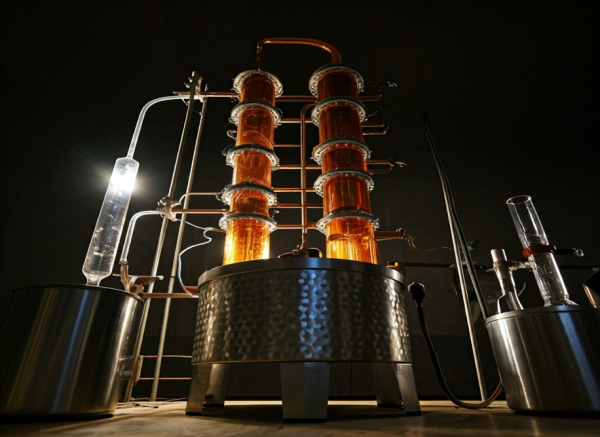

ARNS-21 Atmospheric Distillation Apparatus

The ARNS 21 distillation apparatus is one of the advanced and widely used devices in laboratories and various industries for separating the components of a mixture based on their boiling points. Due to its precise design, high accuracy, and diverse capabilities, this device holds a special place among distillation apparatuses.

Key components of the ARNS 21 distillation apparatus:

- Distillation flask: The container where the sample is placed and heated, causing the volatile components to vaporize.

- Condenser: The part that cools the vapors produced in the distillation flask and converts them back into liquid.

- Receiver: The vessel where the distilled liquid is collected.

- Thermometer: Measures the temperature of the vapors.

- Heat source: Usually an electric element used to heat the distillation flask.

- Temperature control system: Accurately controls the distillation temperature.

Advantages of the ARNS 21 distillation apparatus compared to other devices:

- High accuracy: The precise temperature control system allows for extremely accurate distillation.

- High speed: Due to the optimized design and use of high-quality materials, the distillation speed in this device is very high.

- High reliability: High-quality components and a robust structure increase the device’s lifespan and reliability.

- Easy to use: The simple control panel and user-friendly interface make the device easy to use.

- High safety: Various safety systems, such as an automatic shutdown system in case of excessive temperature increase, ensure safe operation of the device.

- Versatile applications: The ARNS 21 distillation apparatus can be used for a wide range of applications, including the separation of organic compounds, petroleum refining, and determining the boiling point of various substances.

Applications of the ARNS 21 distillation apparatus:

- Petroleum industry: For separating the various components of crude oil and petroleum products.

- Chemical industry: For producing pure chemicals and separating solvents.

- Pharmaceutical industry: For producing drugs and plant extracts.

- Food industry: For producing essences and food extracts.

- Laboratories: For conducting various chemical and physical tests.

Would you like me to translate any specific part of the text in more detail?

Factors Affecting Test Results

The results of the ASTM D86 distillation test are influenced by several factors, including:

- Type of petroleum product: The chemical composition of the petroleum product affects its distillation characteristics.

- Test conditions: Ambient temperature and pressure, heating rate, and type of carrier gas influence the test results.

- Apparatus and equipment: The accuracy and calibration of the testing equipment affect the precision of the results.

- Test procedure: Adhering strictly to the ASTM D86 standard is crucial for accurate results.

Importance of Standardization

The ASTM D86 standard provides a standardized and reproducible method for determining the distillation characteristics of petroleum products. Adherence to this standard ensures that test results are comparable across different laboratories.

Conclusion

The ASTM D86 atmospheric distillation test is a vital and widely used method in the petroleum industry. It provides valuable information about the physical and chemical properties of petroleum products, which is essential for quality control, product selection, and engine performance evaluation. By following the standard procedure and using appropriate equipment, accurate and reliable results can be obtained.

ASTM D86, atmospheric distillation, petroleum products, ArtinAzma mehr, NXA

Sources: