Introduction

In the oil and gas industry, especially in refineries, determining the physical and chemical properties of petroleum products has great importance. One of these crucial properties is the pour point. Pour point refers to the lowest temperature at which a liquid can still flow. This test is particularly essential for lubricants, diesel fuels, and other petroleum products used in low-temperature environments.

As ambient temperature decrease, the viscosity petroleum fluids may increase eventually losing their ability to flow. Knowing a fluid’s pour point helps ensure that equipment and machinery operate effectively in low-temperature conditions. In this article, we will explore the pour point test in detail, review relevant standards, we express the role of the BNTI04-05 from Termex brand

What is the Pour Point Test?

The pour point test is conducted to determine the minimum temperature at which a petroleum product can flow. This characteristic is especially important for ensuring the proper performance of lubricants and fuels in cold temperatures. When the temperature drops to the pour point, the fluid becomes too viscous to move.

Accurate pour point measurement allows engineers and industry professionals to prevent issues such as pipe blockages and equipment malfunctions. Furthermore, considering the various climatic conditions across the world, this test helps engineers choose petroleum products suitable for each specific climate.

Importance of the Pour Point Test in the Industry

In the oil and gas industry, particularly in regions that experience extremely low temperatures, the pour point test has critical importance. When petroleum products are stored or used in cold conditions, it is essential to ensure that they retain their ability to flow and be pumped. neglecting this aspect can lead to significant issues in transportation and operational systems.

For instance, in ships that store diesel fuel for long voyages, the ambient temperature may decrease drastically. In such scenarios, if the pour point of the diesel fuel is too high, the fuel may not flow properly through the pipes, leading to serious problems.

Standards test Method of pour point

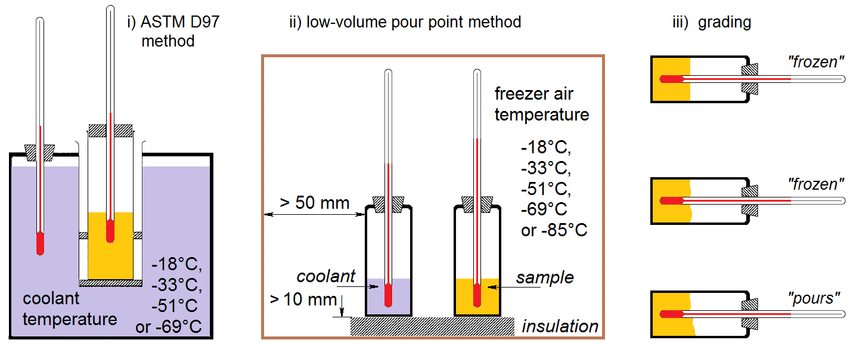

There are some established standards for conducting pour point tests to ensure accurate results. One of the most widely recognized standards is ASTM D97. a procedure suitable for black specimens, cylinder stock and nondistillated fuel oil. This standard outlines the procedure for determining the pour point of petroleum products and is widely adopted in industries across the globe.

According to ASTM D97, petroleum samples are gradually cooled, and their flowability is tested at each stage of cooling. When the sample can no longer flow, the corresponding temperature is recorded as the pour point. This method is precise and reliable, making it the standard choice in various industries.

Role of the BNTI04-05 device of Termex in Pour Point Testing

One of the advanced instruments used for conducting pour point tests is the BNTI04-05 device of Termex. This device, with its high precision and advanced features, provides the necessary conditions for conducting the pour point test effectively.

The BNTI04-05 device of Termex Device is equipped with an advanced cooling system that enables gradual and controlled temperature reduction. This feature allows operators to measure the exact pour point of petroleum samples and ensure their proper performance under different temperature conditions. Additionally, its user-friendly design and control software make the testing process simpler and more accurate.

Features of the BNTI04-05

- High Precision: The BNTI04-05 can accurately control very low temperatures, providing precise measurements.

- User-Friendly Design: The device is designed with a user-friendly interface, making it easy for laboratory operators to use.

- Advanced Cooling System: The sophisticated cooling system ensures uniform and gradual cooling of samples.

- Control Software: The BNTI04-05 is equipped with advanced software that allows users to record and analyze test results easily.

- Automated Processes: The device is equipped with automated systems that handle the entire process of cooling, measuring, and recording results. This feature reduces the need for human intervention and minimizes potential errors.

The Role of Artin Azma Mehr in Providing Laboratory Equipment

Artin Azma Mehr is a leading provider of laboratory equipment, playing a crucial role in enhancing the quality of tests and quality control processes in the oil and gas industry. The company offers specialized and precise equipment, including devices for pour point testing, helping laboratories obtain standardized and reliable results.

Conclusion

The pour point test is one of the most critical tests in the oil and gas industry, helping to assess the performance of petroleum products in low-temperature conditions. The results of this test directly impact the quality and performance of oils, lubricants, and fuels in various temperature conditions. With international standards like ASTM D97, pour point tests are conducted with high precision and accuracy. Artin Azma Mehr plays a significant role in fulfilling the needs of specialized laboratories by offering advanced devices such as the BNTI04-05 device of Termex. This device, with its high precision and efficiency, is an essential tool for any laboratory looking for reliable and accurate results.

Keywords: ASTM D97 standard, BNTI04-05 device, laboratory equipment, Artin Azma Mehr