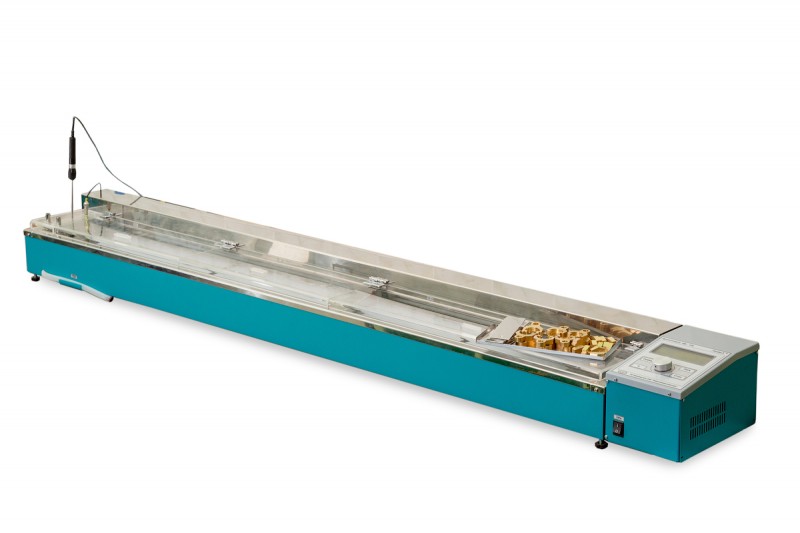

Lintel DB-150 device for determining bitumen flexibility

Lintel DB-150 allows for automatic simultaneous testing of tensile strength (ductility) of 1 to 3 samples

SKU:

lintel-db-150

Category: laboratory equipment

Tags: Laboratory Equipment, NXA, Tensile testing machine

- Lintel DB-150 allows for automatic simultaneous testing of tensile strength (ductility) of 1 to 3 samples

- Adjustable carriage speed in the range from 2 to 1000 mm/min. Accelerated carriage return after testing

- Test logging provides storage of up to 480 test results

- Integration with the Lintel Link data collection system allows for the collection and transmission of laboratory test results from the device to a personal computer via wireless communication. Integration with the Lintel LIS laboratory information system provides comprehensive automation of laboratory activities.

- The built-in pump for mixing the bathhouse coolant together with the heat exchange tubes ensures a minimum temperature gradient in different parts of the bathhouse

- When testing at 0°C, it is possible to connect the thermocryostat “Lintel TKS-20”

- Storing the value of extensibility and sample number by pressing the remote button for fixing the sample break by the operator

- Possibility of checking the temperature sensor readings of the bath with a standard thermometer

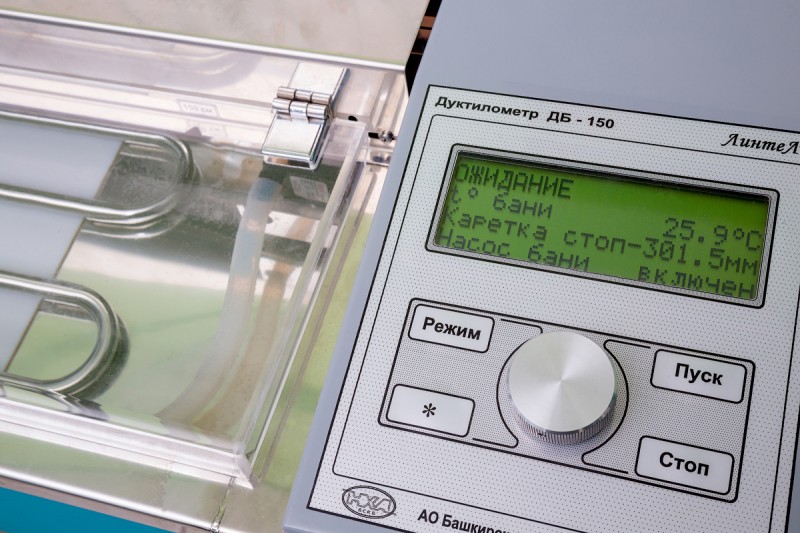

- The liquid crystal display provides an intuitive user interface with all the necessary information when testing and viewing results.

- The set of collapsible forms for samples supplied with the device comply with GOST and provide convenient preparation of samples for testing.

- The device is equipped with a drain pipe with a plug for convenient draining of the coolant.

- The carriage is equipped with a flag, which allows you to track its current position.

- Full self-diagnostic system with indication of causes of malfunctions on the display

- Stopping the testing process at the end of the analysis with an audible signal

Safety

- Electrical safety: Grounding of non-current-carrying parts and compliance with protection class 0I according to GOST R IEC 61140-2000

- Sound accompaniment: Sound signal at the end of the test, detection of a fault

- Diagnostics and setup: Built-in self-diagnostics and configuration algorithms, notifying users about the causes of malfunctions

| Maximum tensile length of test specimens | 1 500 mm |

|---|---|

| Number of simultaneously stretched samples | 3 pcs |

| Maximum load on carriage | 30 kg |

| Carriage speed | from 2 to 1,000 mm/min |

| Temperature measurement error in the working area | no more than ± 0.5 °C |

| Error in maintaining the speed of movement of the carriage relative to the specified one | no more than ± 5% |

| Error in measuring the length of carriage movement (bitumen stretching): - with extension from 0 to 600 mm, | ± 2 mm |

| Error in measuring the length of carriage movement (bitumen stretching): - with elongation more than 600 mm, % | ± 0.3% |

| Dimensions of sample preparation molds | comply with GOST 11505 |

| Power consumption | no more than 70 W |

| Dimensions | 1950x200x300 mm, (width x height x depth) |

| Weight | no more than 30 kg |

| Ambient temperature | from 10 to 35 °C |

| Relative humidity at +25°C | no more than 80% |

| Mains voltage | from 187 to 253 V |

| Power frequency | 49 to 51 Hz |

| Life time | 6 years, no more than 15,000 hours |

| Warranty period | 1 year, no more than 2,500 hours |

| Standards | |

| brand |

هیچ ویدیویی برای این محصول موجود نیست.