Lintel UPSK-10 Device for steam stabilization of catalyst

stabilize the catalyst in an atmosphere of water vapor

Lintel UPSK-10 is designed to stabilize the catalyst in an atmosphere of water vapor in accordance with ASTM D 4463-96.

- The device allows you to prepare up to 4*15 cm3 of catalyst samples.

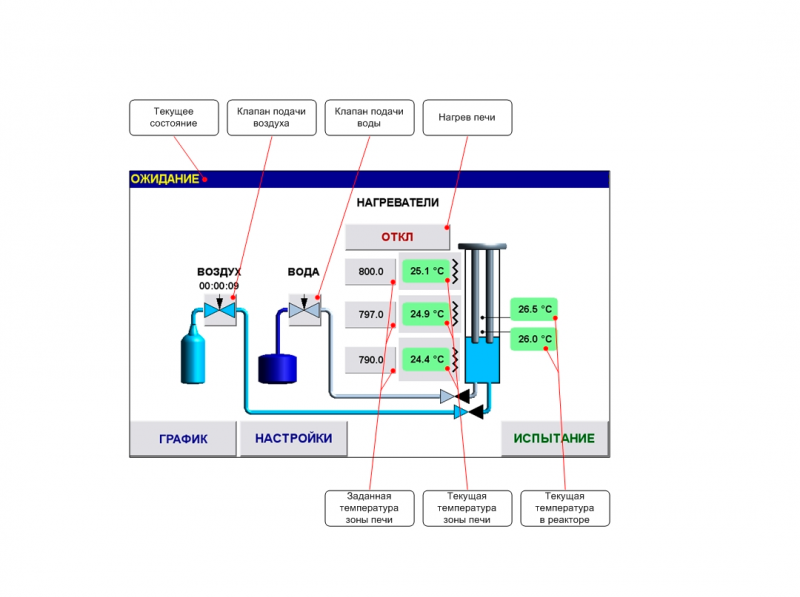

- Lintel UPSK-10 provides automatic maintenance of: catalyst temperature, air flow and steam flow.

- Steam stabilization of the catalyst is carried out according to one of 9 variable programs, consisting of the stages: purge, steam stabilization, final purge.

- The built-in compressor supplies compressed air to the heating unit, without the need for any external sources of compressed air.

- The device allows you to perform tests in automatic and manual mode.

- Convenient system for inserting and removing samples.

- Automatic steam consumption using a peristaltic pump.

- Uniform temperature of the catalyst throughout the entire sample volume is ensured by automatically setting temperatures in a three-zone furnace.

- The color touch display provides detailed information about the set test conditions, current values and measured values during the test.

- Full self-diagnosis system with indication of the causes of malfunctions on the display.

Safety

Electrical safety: Grounding of non-current-carrying parts and compliance with protection class 0I according to GOST R IEC 61140-2000

Sound accompaniment: Sound signal at the end of the test, detection of a fault

Diagnostics and setup: Built-in self-diagnostics and configuration algorithms, notifying users about the causes of malfunctions

| Reactor loading volume | up to 4*15 cm3 |

|---|---|

| Oven temperature | from 700 to 850°C |

| Air flow | from 1 to 7 cm/s |

| Steam consumption | from 2 to 50 cm/s |

| Accuracy of maintaining temperature from 700 to 850°C | ±2.0°С |

| Accuracy of maintaining air flow from 1 to 7 cm/s | ± 10% |

| Accuracy of maintaining water flow from 0.2 to 5.5 ml/min | ± 10% |

| Power consumption with thermostat off | no more than 50 VA |

| Power consumption with thermostat on | no more than 6000 VA |

| Overall dimensions (width x height x depth) | 1100 x 1200 x 550 mm |

| Weight | no more than 180 kg |

| Ambient temperature | from +10 to +35 °C |

| Relative humidity | no more than 80% |

| Atmosphere pressure | from 90.6 to 106.6 kPa |

| Voltage | from 187 to 253 V |

| Frequency | 49 to 51 Hz |

| Life time | 6 years, no more than 15,000 hours |

| Warranty period | 1 year, no more than 2,500 hours |

| Standards | |

| brand |

هیچ ویدیویی برای این محصول موجود نیست.