Introduction

Density is one of the most important physical properties of materials, providing key information about the structure, composition, and behavior of a substance under various conditions. This property is particularly significant in the oil, gas, petrochemical, food, pharmaceutical, and environmental industries. Density testing is one of the most fundamental laboratory analyses, playing a crucial role in both quality control processes and research studies.

Physical Concept of Density

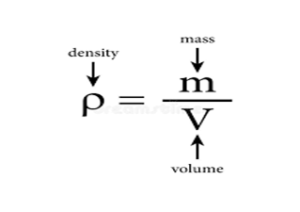

Density is one of the most important fundamental physical properties of materials, representing the amount of mass contained in a unit volume of a substance. In simpler terms, density indicates how “heavy” or “light” a material is relative to its volume. This property is used in volumetric analyses, industrial process design, fluid dynamic behavior studies, energy calculations, and even in determining the purity of a substance.

Density formula:

Where:

Mass: measured in kilograms (kg) or grams (g)

Volume: measured in cubic meters (m³) or cubic centimeters (cm³)

Different Systems for Expressing Density

| System | Unit | Symbol | Description |

|---|---|---|---|

| SI (Metric) | Kilogram per cubic meter | kg/m³ | Most common scientific unit |

| CGS | Gram per cubic centimeter | g/cm³ | 1 g/cm³ = 1000 kg/m³ |

| Industrial (Oil & Fuel) | API Gravity | °API | Based on specific gravity at 60°F |

| General Laboratory | Gram per milliliter | g/mL | Equivalent to g/cm³ for liquids |

What is Specific Gravity?

Specific Gravity is the ratio of the density of a substance to the density of a reference material (usually water at 4°C or 15.6°C). This quantity is dimensionless (unitless) and is widely used in the oil and chemical industries.

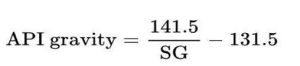

API Gravity in the Oil Industry

In the oil industry, instead of density, API Gravity is often used, which has an inverse relationship with specific gravity. This index helps easily determine whether a petroleum product is “light” or “heavy”:

- High API → Lighter fuel (such as gasoline)

- Low API → Heavier fuel (such as fuel oil)

Why is Density Important?

Laboratory Applications:

- Identification and comparison of materials

- Determination of sample purity

- Calculation of solution concentrations

Oil and Petrochemical Industry:

- Quality control of products (gasoline, diesel, oils)

- Determination of API and fuel pricing

- Mass-to-volume and volume-to-mass conversions (for trade and transportation)

Pharmaceutical and Food Industries:

- Ensuring product uniformity and compliance with standards

- Monitoring the concentration of syrups, milk, and liquid-based products

Environmental Applications:

- Assessing pollutant density in wastewater or industrial effluents

- Detecting chemical or oil spills in water sources

Effect of Temperature and Pressure on Density

Effect of Temperature:

- Rising temperature increases molecular motion, causing materials to expand. This expansion increases volume and reduces density. For example, warm air has a lower density than cold air.

- For liquids and solids, increasing temperature usually decreases density, but the effect is less pronounced than in gases.

Effect of Pressure:

- Increasing pressure compresses materials. In gases, higher pressure significantly increases density because gas molecules are forced closer together.

- For liquids and solids, the effect of pressure on density is usually minimal since these materials are generally less compressible than gases.

- Temperature–Density relationship: Inverse (as temperature increases, density decreases)

- Pressure–Density relationship: Direct (as pressure increases, density increases)

Different Methods for Measuring Density

Hydrometry Method – in accordance with ASTM D1298

The hydrometry method is one of the classic and widely used techniques for measuring density, specific gravity, and API gravity in liquids. In this method, a simple instrument called a hydrometer is used to determine density.

hydrometer is a cylindrical glass device with a bulb-shaped reservoir at the bottom and a graduated stem at the top. It is placed into the liquid, where it floats at a depth corresponding to the density of the fluid.

Applications

- Measuring the density or API of gasoline, kerosene, diesel, and oils

- Quality control and specification determination of petroleum products

- Calculating specific gravity and converting volume to mass

- Monitoring fuel compliance in terminals and laboratories

Required Equipment:

- Hydrometer

- Tall glass cylinder

- Precision thermometer

- Temperature-controlled bath

- ASTM D1250 temperature correction table

Test Procedure:

- Sample preparation

Filling the cylinder

Placing the hydrometer

Reading the density value

Measuring the temperature

Correcting results using the D1250 table

Advantages and Disadvantages

| Advantages | Disadvantages |

|---|---|

| Simple and inexpensive | Lower accuracy compared to digital methods |

| Suitable for field use | Dependent on ambient temperature |

| Requires minimal equipment | Prone to operator error and air bubbles |

| No need for electricity or complex calibration | Suitable only for clear and homogeneous liquids |

Accuracy and Repeatability

The accuracy of the ASTM D1298 method is typically around ±0.001 g/cm³. Operator experience, cleanliness of containers, sample homogeneity, and temperature conditions have a significant impact on result reliability.

Digital Densitometer – According to ASTM D4052

The digital densitometer operates on the principle of oscillations in a U-shaped tube. ASTM D4052 is the reference standard for measuring the density and specific gravity of liquids using a digital densitometer under controlled temperature conditions.

In this method, a vibrating U-shaped glass tube is used. When the sample is injected into the tube, the oscillation frequency changes. The oscillation frequency is related to the mass of the sample inside the tube and follows the equation:

f = k × √(1 / m)

Where:

- f: Oscillation frequency of the tube

- m: Mass of the sample in the tube

- k: Constant dependent on the mechanical properties of the system (such as tube stiffness and design)

By precisely measuring the oscillation frequency and knowing the fixed volume of the tube, the density of the material can be calculated with high accuracy. Due to its high precision, fast response time, and low sample requirement, this method is widely used in the oil, chemical, food, and pharmaceutical industries.

Key Specifications:

| Feature | Value |

|---|---|

| Measurement range | 0.7 to 1.5 g/cm³ |

| Sample volume | 0.5 to 2 mL |

| Accuracy | Up to ±0.00001 g/cm³ |

| Test time | 2–5 minutes |

| Temperature control | Precise, with built-in thermostat |

Advantages:

- Extremely high accuracy

- Very low sample volume required

- Connectivity to software and printer

- Simultaneous measurement of density, SG, and API

- Suitable for various liquids

- Automated and low-error operation

Test Procedure:

- Calibration

- Sample injection

- Temperature stabilization

- Measurement

- Reporting

Comparison with Hydrometry Method:

| Feature | ASTM D4052 | ASTM D1298 |

|---|---|---|

| Instrument type | Digital | Manual |

| Accuracy | Very high | Moderate |

| Sample volume | Low | High |

| Test time | Fast | Slower |

| Temperature control | Automatic | Manual |

| Operator involvement | Low | High |

Applications:

- Refineries

- Chemical industries

- Pharmaceutical and food industries

- Environmental laboratories

Calibration and Maintenance:

Performed using reference materials and cleaning the tube with a suitable solvent.

VIP-2MP Densitometer – TERMEX Brand

The VIP-2MP by TERMEX is a precise and user-friendly benchtop densitometer designed for measuring the density of liquids and crude oil in accordance with ASTM D4052 and ASTM D5002 standards. This instrument measures sample density with an accuracy of ±0.0001 g/mL, covering a range up to 3 g/mL, and operates within a temperature range of 15°C to 60°C.

Its operating principle is based on measuring the oscillation frequency of a U-shaped tube filled with the sample. The device uses two calibration references (water and dry air) to calculate the density value.

Artin Azma Mehr Co., the official and exclusive representative of TERMEX in Iran, supplies this device along with related technical services.

Pycnometer Method – Based on ASTM D70 and ASTM D941

The pycnometer method is a classic and highly accurate technique for measuring density, particularly suited for liquids, fine-grained solids, and semi-solid materials such as bitumen (asphalt), grease, and heavy oils. Due to its simplicity, high precision, and minimal equipment requirements, it is still widely used in many quality control and research laboratories.

A pycnometer is a container with a precisely known volume, typically made of glass or metal. It features a cap with a fine hole to allow excess air to escape and to ensure a uniform liquid surface. After filling, the container is weighed with high accuracy, and the density is calculated using the formula:

Where:

- P: Density in grams per cubic centimeter (g/cm³)

- M: Mass of the sample inside the pycnometer (g)

- V: Exact volume of the pycnometer (cm³)

Relevant Standards and Applications

| Standard | Application |

|---|---|

| ASTM D70 | Density of bitumen, asphalt, and semi-solid materials |

| ASTM D941 | Lubricating oils, transformer oils, and industrial liquids |

Principle of the Method

Density is determined by weighing the pycnometer when empty (W₁) and when filled with the sample (W₂), and dividing the mass of the sample by the exact volume of the pycnometer:

Density = (W₂ − W₁) / V

- W₁: Mass of the empty pycnometer

- W₂: Mass of the pycnometer with the substance

- V: Exact volume of the pycnometer

Test Procedure

- Calibration with water

- Sample preparation

- Filling the pycnometer

- Temperature stabilization

- Precise weighing

- Density calculation

Advantages vs. Disadvantages

| Advantages | Disadvantages |

|---|---|

| Very high accuracy | Time-consuming process |

| Suitable for viscous materials | Requires precise balance and temperature bath |

| Less temperature-sensitive than hydrometers | Prone to contamination and sticking |

Key Notes

- Use a high-precision balance

- Maintain accurate temperature control

- Remove all air bubbles

- Ensure complete cleanliness of the pycnometer

Applications

- Measuring the density of bitumen and asphalt

- Quality control of industrial oils

- Transformer oil testing

- Academic and research studies

Conclusion

Density determination is one of the most important and fundamental physical tests in the chemical and petroleum industries, providing valuable information about the properties and quality of materials. Density is not only an accurate criterion for identifying and comparing samples, but it also plays a key role in quality control, industrial process design, and evaluation against international standards.

Different density measurement methods each have their own advantages and limitations:

- Hydrometry method (ASTM D1298): Due to its simplicity, low cost, and field usability, it is suitable for general applications and transparent samples.

- Digital densitometer (ASTM D4052): With very high accuracy, fast testing, and minimal operator intervention, it is the optimal choice for advanced laboratories and precise quality control.

- Pycnometry method (ASTM D70/D941): The most accurate method for viscous or semi-solid samples and the best option where high precision is essential.

Artin Azma Mehr Company, as the official and exclusive representative of reputable brands including TERMEX in Iran, supplies advanced density measurement devices and equipment and also provides specialized technical services.